9 Most Common Central Heating Pump Problems [And Pump Fixes]

You don’t have to be a plumber to identify central heating pump problems.

For example: Is your boiler making noise or leaking? Are your radiators cold even though you’ve just cleared them of all sludge build-up? Then a faulty central hot water pump may be the culprit.

A malfunctioning central heating pump can cause a range of problems with your entire heating system, including leaks, excessive noise, cold radiators, and more.

In this post, we’ll examine 9 of the most widespread heating pump issues, their causes, and optimal solutions.

If you’ve got an older boiler and you suspect it’s causing the problems you’re experiencing, you can learn more about boiler replacement costs here. Otherwise, read on to find out more!

What is a central heating pump?

A central heating pump in a central heating system takes hot water from the boiler and pumps it around the pipework in your property. This feeds the radiators, taps, towel rails and showers in your property.

A central heating pump in a central heating system takes hot water from the boiler and pumps it around the pipework in your property. This feeds the radiators, taps, towel rails and showers in your property.

If a central heating pump is not working, it can wreak havoc on your whole heating system. Often, a noisy central heating pump is the telltale sign that something is amiss.

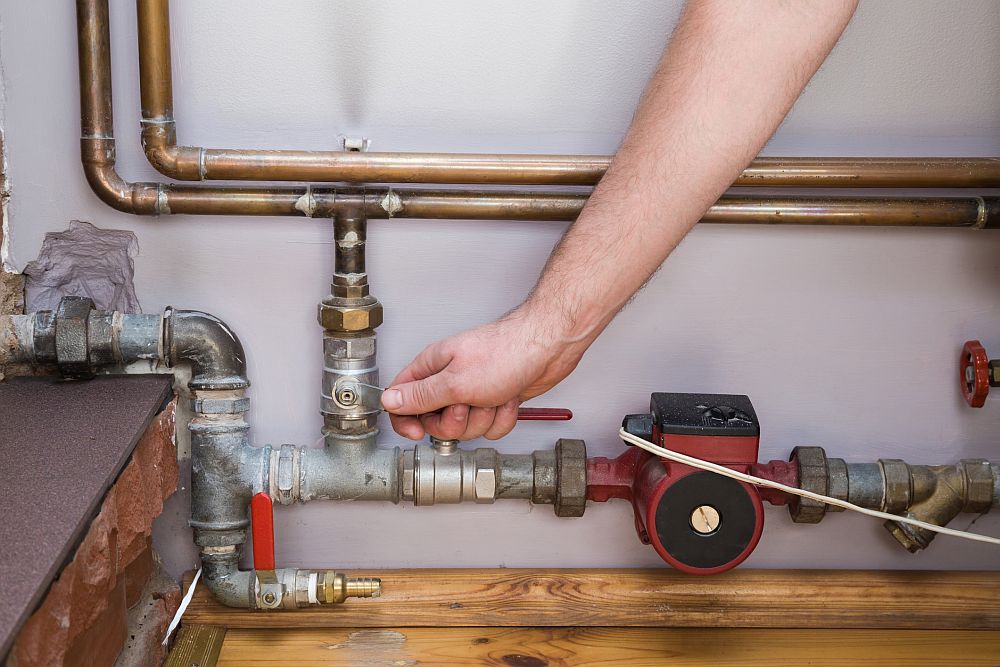

Where is the pump located?

If you have a regular or system boiler, the central heating pump will be located next to the boiler, or in an airing cupboard.

If you’ve got a combi, on the other hand, you won’t need an external pump for domestic hot water or heating. The tap water already gets supplied at mains pressure, whilst combis typically have an integral pump to circulate water through your radiators.

We’re going to cover the most common heating pump problems and what can be done to fix them (or, how much central heating pumps cost to fix).

Central heating pump not working? Check these problems

Pump Problem 1: The pump is running, but it’s not pumping water around the system

If the central heating pump is running, then it should be vibrating slightly. The most likely cause of this problem is that the shaft or propeller on the pump is stuck.

On some occasions (especially when the motor is extremely hot), the pump’s motor is the problem. The pump will get warm, but it shouldn’t be hot to the touch.

This is particularly common on heating systems that have been left sitting for a while.

The Fix

If a component on the pump is stuck and the pump is not circulating water, sometimes a gentle tap will free up any seized components.

If the seizure is happening on a regular basis, it’s a good sign the heating pump is on its way out and is likely to fail altogether.

A replacement pump is likely to cost £200-250 including installation. This is about what you’d expect to pay for a top-quality Grundfos central heating pump.

Check out our related article covering heating and boiler problems here.

Pump Problem 2: Pump is blocked full of dirt

As central heating systems age, dirt and metal particles from radiators and pipework break down and begin to flow through major components such as the heating pump. This dirt and grime builds up in major components in the boiler and causes them to fail. Luckily, pump blockages are quite easy to fix, as all it requires is a little bit of cleaning.

It’s common for the boiler pump to build up with dirt and then stop working correctly. When this happens, you’ll find your heating system heats up slowly, not to full temperature, or not at all.

The Fix

The first point of call would be to hot flush the heating system with chemicals. This differs to a power flush as it doesn’t increase the pressure in the system. Increasing the pressure on old systems can weaken joints and components and cause leaks.

Once you’ve flushed the system and the pump is clean, a good preventative measure is to fit a magnetic system filter.

The magnetic system filter will catch a lot of the debris and help to prevent any future heating pump problems.

Always ask an engineer to check the heating pump when they come to do an annual boiler service.

Pump Problem 3: Airlocks & noisy central heating pumps

Another common heating pump problem is air locks. If air builds up in the pump, the pump will stop working correctly.

Many central heating pumps have a bleed screw that can be used to remove the air, and allow the pump to work again without replacing any internal parts.

If you hear noises coming from the central heating pump that doesn’t seem normal, airlocks are likely to be the problem. A lot of customers complain of a constant humming noise when airlocks are the problem.

The Fix

Once you’ve located the pump on the boiler, look out for a small central heating pump bleed screw. Please bear in mind that the pump is full of water. Open the screw extremely slowly (less than a quarter of a turn will usually be enough) as there is likely to be a small amount of water leaking out of the pump once all the air is bled.

If this doesn’t fix the problem, it’s likely the pump noises have always been there. Some manufacturers supply anti vibration brackets which are easy to install with the right tools.

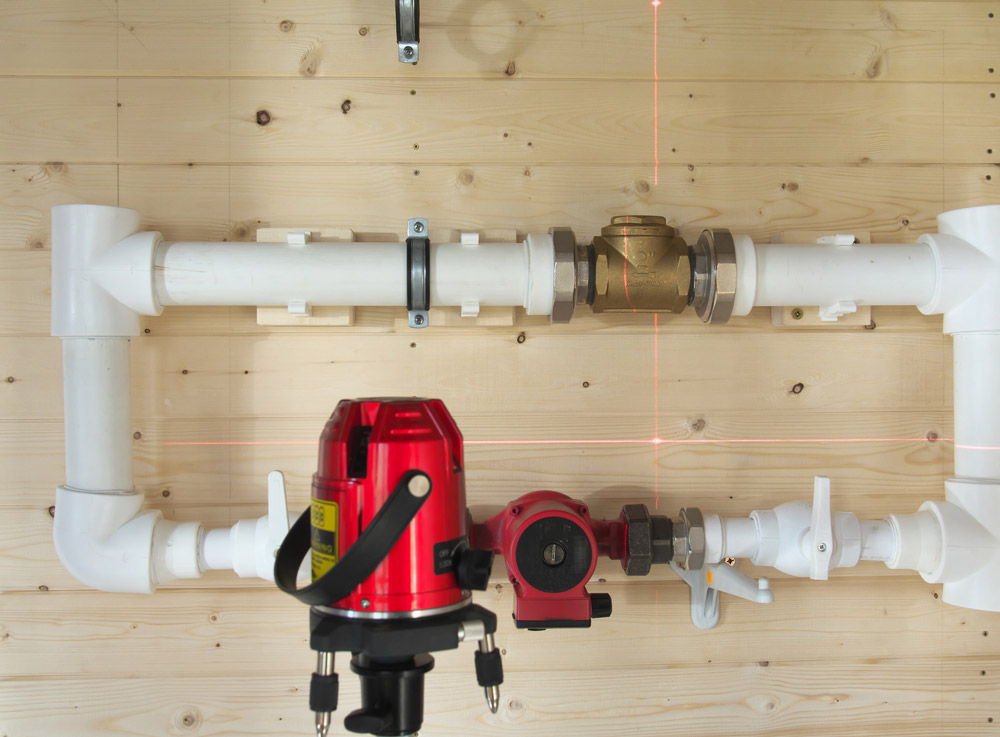

Pump Problem 4: Incorrect product installation

Not all heating pump problems can be blamed on the pump. If the system has never worked correctly, there’s a small chance that the central heating water pump may have been installed incorrectly. In a worst-case scenario, the original installer fitted the pump the wrong way.

The Fix

This is extremely uncommon, but if the pump has been fitted incorrectly, then it needs to be switched around. Remember, you must drain the system before removing and turning the pump.

After refitting the pump, you’ll have to fill the system using the filling loop on the boiler. And remember, you’ll also need to bleed all the radiators and towel rails.

What kind of fuel does your boiler use?

Fixed price online with next day installation

Pump Problem 5: Pump speed settings are incorrect

Newer pumps (such as the Grundfos central heating pump 15/60) will have speed and flow settings. They are extremely easy to adjust.

And usually they are between 1 and 3. 1 is the slowest water flow rate and 3 is the highest. On many properties, we have been to that have had radiators not getting hot, or the whole system not getting to temperature, the pump flow rate is the issue.

The Fix

Locate the boiler pump. On top of the pump will be a switch. If this switch is set to 1 or 2, there’s a good chance that the flow rate is too low. You can flick the pump to 3, which is the most powerful setting.

It’s worth consulting a Gas Safe engineer or your central heating cover provider. The heat pump central heating may be set at 1 or 2 for a reason (such as a system doesn’t allow any further flow due to microbore pipes). Turning the setting up on a system that doesn’t require it could result in leaks or broken components in the boiler.

Pump Problem 6: Leaking pump

Boilers leak for a whole host of different reasons. One of the most common reasons that a boiler leaks is issues with the pump. This can be down to incorrect installation, the pump working itself loose, or even a blown seal due to incorrect pressure settings.

The Fix

Check that the pump is secure. If it’s not, tightening it up can sometimes be enough to stop a water leak.

Check all the fittings on the pump. Corrosion maybe the cause of the water leak. If this is the case, you’ll need to fit a new central heating pump.

Finally, check the joint on the pump. If this is what is leaking, there’s a good chance that it’s the seal on the pump that is blown.

The two options here are to replace the seal, or replace the pump. If the pump is particularly old, a replacement is the best option. Read our guide on boiler installation costs, or go ahead and request a replacement here.

Pump Problem 7: No power

If the pump and boiler have no power, but your property has power, the likely cause is going to be the PCB unit. Hopefully, your boiler has power. If it’s just the pump that has no power (or won’t start up) there’s likely a wiring issue. On some occasions, small leaks can ruin the wiring on the pump.

The Fix

First, start with the easy and obvious. Like other appliances pumps have fuses. Check that the fuse isn’t blown.

Also, check that are no leaks. If there isn’t, have a Gas Safe engineer come and check the wiring to the pump.

If the pump is old and corroded, there’s a good chance that other parts are going to fail and a replacement is likely in order.

Prefer a new boiler with a long warranty? Get your price online using this clickable form.

Pump Problem 8: Pump won’t turn off

Most pump problems are related to pumps not working. However, on rare occasions we are called out to boilers where the pump constantly runs and won’t switch off. We’ve seen this to be a problem with the Baxi Solo range on a number of occasions.

The Fix

A proper pump diagnostic needs to take place. In the past, we’ve seen pumps constantly running due to:

- Faulty PCBs (the circuit board on the boiler).

- Pump overrun stat is faulty.

- The mid position valve is sticking (this can be lubricated with WD40).

Pump Problem 9: Pump is worn out

Like any other mechanical device, a central heating pump can succumb to wear and tear associated with age. You can expect the pump to become worn out after about 15 years of service, but some can last as long as three decades.

If you’ve eliminated every other problem on this list, chances are that the pump is simply worn out and due for replacement.

The Fix

If your central heating pump has lived past its useful service life, it’s simply time to get a new one. You can learn more about replacing central heating pump services, and the expenses you can expect, by clicking here.

Faulty Central Heating Pump: Conclusion

Whether you have a noisy radiator, a boiler making loud noise like running water, or you simply suspect your old central heating pump has gone, a fix is close to hand.

There are several telltale signs something has gone wrong, and we’ve covered 9 of the most likely problems with hot water pumps. Read our guide carefully for a solution, or else reach out to a professional to help if nothing is forthcoming.

If you have any questions relating to central heating pump problems, please leave a comment below and we’ll get back to you.

Could you please advise me on correcting a problem on why the central heating pump continues to run when both heating and hot water have been switched off at the controller.

Many thanks

Howard Evans

If it’s just for a minute or two, don’t worry. It’s pumping excessively hot water from your boiler so it doesn’t cause any damage.

It needs a diagnostic, but a good start is checking the pump is communicating properly with the PCB via the heat sensor.

I have a firebird super q 50/82.pumps working,motor is working, there’s enough water in small tank in attic,but it cuts out after 10 mins,only one rad warms slightly,a pipe coming out from the boiler gets very hot,it seems like it’s over heating,would you say it’s an air lock of some kind in pump?or is there a thermostat that could be gone? any suggestions of what it might be,will I need a pro to look at it?

Hi Martina,

Could be a tonne of things. But, sounds potentially like sludge in the system, air locks or bad piping (microbore when it shouldn’t be for instance).

Starting with air locks, you can bleed the rads with a drain key. If that doesn’t work, I’d look at getting an engineer out.

Cheers

Paul here,I have a combi boiler & the pump is very hot, im getting hot water, but no central heating. I assume my pump is jammed internally, but removing screw to access it, is the issue, as there seems to be constant high water pressure there when I slowly unscrew it.

Hi

I want to change my central heating pump but not sure which on to get. I have 15 radiators in my house, so would a standard one be ok?

Many thanks Andy

Hey Andy,

It’s not just the amount of radiators. It’s the size and total distance of the heating pipes that water has to travel through.

There’s a size guide on the Grundfos website that’s worth a look: https://uk.grundfos.com/grundfos-for-engineers/sizing-and-selection.html

If that doesn’t help, I’d have an engineer come spec one for your property.

Hi. I have recently had two new radiators downstairs the central heating was all working fine but recently one of the radiators doesn’t work when the system is cold to get it to warm up I have to turn half the other radiators off in the house and after a short time you can hear the radiator bubble then it will warm up after turning all the radiators back on I bleed them all and a little air does come out. I have been doing this for 3 weeks now is there something that is causing the air to get in to the system? I have a condensing boiler many thanks

Hey Nathan,

Potentially a leak allowing air to enter. Most probably from one of the valves on the new rads, are they leaking?

Details on airlocks in rads: https://heatingforce.co.uk/blog/noisy-radiators/

Leaks will lead to a loss in boiler pressure, so if that’s the case: https://heatingforce.co.uk/blog/boiler-losing-pressure/

Hi

I have a radiator problem….the radiator in living room is a double panel radiator but its not hot compared to other single panel radiators…. there is two pipes coming to the radiator in which one pipe is cold….can anyone tell what will be issue….

Is the whole radiator the same heat? https://heatingforce.co.uk/blog/radiators-cold-at-the-bottom/

If it’s cold at the top instead, that’s a sign of an air leak.

And, if it’s the last radiator on the heating run, it might be the pump isn’t set to a high enough flow setting (or doesn’t have the flow capacity).

Hi, I have an Ideal Logic heat 24 boiler. Noticed the thermostat wasn’t turning the boiler off, so naturally turned the programmer to off. Didn’t stop the boiler, but turning down the min max on the boiler did. Noticed however that the pump continues to run, seems the only way to stop the pump is to cut the power to the boiler. Any idea if there’s a fix I can attempt or is it engineer time?

Cheers, Jonathan

Hey Jonathan,

This should help, https://heatingforce.co.uk/blog/boiler-timer-not-working/

But, I’d call an engineer to make sure there’s not anything more serious.

Hi. We have just installed a new Grundfos pump and it makes a loud humming noise that vibrates through the pipes. We have checked the installation and bleed it but it makes no difference. Is there anything else we can try? Thanks.

Hi Cheryl,

There’s a lot of things it could be, so I’d get a boiler repair specialist in, or contact Grundfos.

Pump could be too large/too high a speed setting. It could be too small, so water is overheating.

By “checked the installation”, what do you mean? Are you sure the pump’s shaft is horizontal?

They have 2 technical contact numbers:

01525 850000

01942 263628

Hope that helps

Hi, my radiators heat up when boiler is on. Once it does, the boiler switches off and radiators go from too warm to completely cold as if everything is switched off until boiler switches on again. This cycle continues all day.

Shouldn’t the radiators be constantly warm with continuous circulation even when boiler is off? Is the problem with pump? Please advice so that I know what I’m talking about when I call the BG engineer.

Hi Bharath,

Assuming you have no cold spots on your radiators once they’re heated, and they heat/cool down in tandem, I’d lean towards a thermostat issue. It’s quite hard to diagnose without seeing the property, but that’s usually the case.

Hi, Since we had a new Grundfos Alpha2 pump installed the boiler has been cutting out. We’ll be without heat and water for hours then it will kick in for 10 minutes and then switch of again. Or the heating will be on and on irrespective of the temperature on the thermostat. Since the new pump we replaced the valve, thermostat and the timer and the boiler still cuts out.

Do you think this is an issue with the pump?

Many thanks

Bulent

Hi Bulent,

There could be a tonne of issues, but as you’ve just had a new pump fitted, I’d speak to Grundfos first:

01525 850000

01942 263628

hi

our heating does not warm the radiators when boiler is on’ but the hot water get hot ,i have looked at the pump it does seem to be working but when i try to change the speed it makes no difference the pump seems to work on the same speed what ever setting i put it on

i can feel it vibrating so it is doing something but not what it should do

any ideas

Hey Neil,

Do the radiators heat up at all? Is the problem with radiators upstairs/downstairs, or both?

More info here: https://heatingforce.co.uk/blog/boiler-fault-finding/

Hi. My radiators are hot upstairs but cold downstairs. I have loft tank, hot water tank with pump on 1st floor and boiler downstairs. 7 rads upstairs with 6 rads downstairs.

This seems to be common problem and lots of threads online. Based on those i think I’ve done the obvious things….

1. Check pump – seems to be running if a bit hot. Released the air in the pump and checked it’s not seized.

2. Checked the water tank upstairs. Water seems to be filling when the valve is open.

3. Tried to balance the rads. No luck. When all rads upstairs are turned off, i can get heat to most of the rads downstairs. But as soon as I make a quarter turn on any rads upstairs I lose all heat downstairs.

4. Motorized valve is operating.

5. Not running any zones and one thermostat downstairs is operating.

Not sure what to try next other than call someone out.

Any advice would be gratefully recieved.

Hey Ali,

Has the problem always occurred, or just recently?

Have you ever done a hot flush, and do you have filters catch scale/rust (scale reducer & magnetic system filter: https://heatingforce.co.uk/blog/magnetic-system-filters/)

Do you have microbore copper pipework anywhere (8mm/10mm)?

What boiler, and what size property (average 4-bed for instance)?

Thanks

Hello, we’re finding that our downstairs radiators are only working with the upstairs ones switched off. The radiators also don’t seem to be cooling down when the control panel is set to off. We’ve also recently noticed a drop in hot water pressure, if the turn the shower and bath tap on and off again, pressure comes back but only for a short time. Could these be signs that our pump needs to be replaced?

Thank you!

Hi Rosy. I’d get an engineer to balance the rads and check the pump’s flow setting.

The pressure will go up slightly when the boiler is operational: https://heatingforce.co.uk/blog/what-pressure-should-my-boiler-be/

Our “Potterton heatmax combi” boiler is dripping clean water from the bottom left. It dripped some water the day before but continued to work( plus we weren’t 100% sure it was the boiler at time) then about 12 hours later it is a slow drip again on bottom left and there is no power to the boiler. Turned it off at the wall and unsure what is wrong( costly?!)

Hi Sandra,

Would need someone to look & diagnose the fault unfortunately.

https://heatingforce.co.uk/blog/boiler-leaking-water-from-bottom/

Thanks

I have Grunfoss Pump that all of a sudden is making a noise….but one day it is ok then the next it’s noisy again, it may go 2 days and not make a sound then it starts again. The ch and hw work fine and boiler seems fine too. Why is it noisy only intermittently????? it’s 4 years old. What is wrong with it…bleed it via silver screw and it dribbled water, no hiss of air.

Turned the heating on for the first time last night. The boiler kicks in and the radiators heat up, then the rcd trips after about 5mins. The pump and valve seem fine. What else can it be?

Hey Jane,

Take a look at this I wrote here: https://heatingforce.co.uk/blog/noisy-central-heating-pump/

Thanks for that, but would these be intermittent?? today not a sound again!! i thought if broken inside it would be constant or am I wrong in thinking that. I have been advised to change pump but as it does not happen all the time I feel reluctant but please advise me if i should really. many thanks.

NEW BUILD HOUSE, HEATING SYSTEM NOISE LEVELS UNCOMFORTABLE . HAVE TO SWITCH SYSTEM OFF ON EVENING SO GRANDDAUGHTER CAN SLEEP. NOISE IN AIRING CUPBOARD UPSTAIRS, IN LOUNGE BELOW, IF HEATING ON HAVE TO TURN T/V VOLUME UP TO OVERCOME NOISE LEVEL FROM HEATING. NEW PUMP FITTED RECENTLY BUT STILL NOISY.

NOISE SEEMS TO BE GREATER AT FLOW TO PUMP. BOILER APPEARS OK SERVICED LAST YEAR NO ONE HAS COME UP WITH A SOLUTION.

HOT WATER CYLINDER WAS ALSO SERVICED THEY SAID SYSTEM WAS NOISY AT THIS POINT BUT OFFERED NO SOLUTION

That does sound noisy!

If you scroll down, there’s 4 articles on noisy boilers, pumps, heating, pipes etc

https://heatingforce.co.uk/blog/boiler-fault-finding/

About 3 months ago I got a new Grundfos water pump for my central heating system. I have a Baxi Solo boiler, and the water tank and pump are in the airing cupboard in the spare bedroom.

When the heating comes on in the morning, the pump has started to make a loud noise, it’s quite high pitched, and the boiler also seems to be quite loud (making a humming sound). Both seem to be loud at the same time.

However, the noise isn’t permanent, it comes and goes. The pump will be noisy for maybe 20-25 minutes, then it goes back to normal again, then it will start again after a while.

Before I got the new pump, the system was drained as I had a problem with a downstairs radiator. Once the problem was fixed, all radiators were bled except two in the living room as the valves are broken and those radiators cannot be bled.

Could my problem be an airlock in the system?

Hey Stuart,

There’s two guides on noisy boilers/noisy pumps here – hope they help…

https://heatingforce.co.uk/blog/noisy-central-heating-pump/

https://heatingforce.co.uk/blog/noisy-boiler/

What is the central screw on top of the pump for on a central heating pump ?

Hi

Boiler ok

Pump ok … I think

As . Hot radiators up stairs, two mildly warm down stairs , but the rest don’t heat at all

System has been flushed …little rubbish inside…

Refilled with rad cleaner, still no better

Please help

I would say the pump is not in good condition. You’d need an engineer to be sure of that.

This evening I noticed our Grundfos heater pump has been on constantly, I switched off the mains and then switched power back on to see if this would correct the problem. Now the pump starts and then switches off after a couple of seconds, any ideas as to why ? We had the pump replaced about 5 years ago, when we had the same problem.

Seems like a faulty pump.

Hi,

We have been informed today that the pump that was fitted (by BG) a number of years ago is incorrect – it is a 50/60 (grundfos) however the manufacturers pump (also grundfos) is a 15/60

What effect would this have had over the years. We have central pipes of 22mm reducing to microbore to run to radiators

My boiler is giving hot water and can hear it humming but when I switch it to both water and radiators it’s not making a noise just silence and no heating but hot water can you please advice

I have 9 rads on one level flat, I get full heat on individual radiator but can only get any 4 to heat together

Hi! This is gonna sound crazy but when I lean on my bed/floor the boiler turns on and when I let go of the pressure it turns off. Any idea what it could be please?

If the heated water pumped does not reach the 3rd floor (attic) what does that mean?: Pump not working correctly, pump is broken though it is lit up like it always did, leakcage (not visible anyway) Air trap ? It would be good to know before I call the profis!

It could be ANY of these, honestly.

I’m having trouble with my electric central heating. I turn it on and after 30 secs it locks out I turn the power off and back on and the water pump isn’t running then after four or five attempts the pump starts and everything is working until the next time I put the heating on

I just replaced the batteries in my thermostat. When I turned my heating on, I heard a click for the boiler to start and then a groaning humming sound as if something wasn’t connecting. Could it be the pump. Both the pump and boiler are about 5 years old. Dont know whether to call electrician or plumber or both

I would say it could be both, just not sure in which order. Try to see if the wires are well connected. And definitely make sure the pump works fine, now that the cold season is coming.

Hi, I have to turn off the boiler on and off a few times to get it the pump to start pumping around the system and not go into lockout mode on the boiler. Every day I have to do this before I can get it to stay on so I can get hot water and heat. It’s an electric boiler I have. Any suggestions. Thanks

I have a grundfos 16/50 installed in the airing cupboard and it’s upside down and there’s a lot of noise when the heating is on. Constant. Sounds a bit like boiling water but not noise not coming from the water tank.

Definitely noisy. See if these tutorials help?

https://heatingforce.co.uk/blog/noisy-central-heating-pump/

https://heatingforce.co.uk/blog/noisy-boiler/

Just bought a house with 11 large double radiators and 2 towel rails. The guy who had the house before had them changed from singles to doubles, but didn’t change the pump-it is a 2 speed grundfos super 4.

2 double radiators do not get hot at all and 1 double radiator heats but not to a sufficient temperature.

It is not a modern system as we have a cylinder in the airing cupboard, and the boiler itself is an Ideal Standard free standing boiler.

I have drained and refilled but the problems remain.

I think the pump is probably not powerful enough to cope with the bigger radiators.

Any input you can give and advice on what to replace the pump with (if needed) would be gratefully received.

Hello,

heating (pump) works perfectly from basement to first floor. Thesecond floor radiator have no heat! What could this be?

1) Air lock

2) Weak pump or???

Help.

Thank you,

Robert

Hi Robert, it could be both.

hi moved into my property 3 months ago ,radiators get hot upstairs and some do downstairs but not all at least 2 are stone cold ,I have changed the motorised valve head on the 3 port valve and also the pump ,we have cleaned the system and flushed it out twice ,the pump gets to hot to touch and have tried all 3 settings on the pump but has not made a lot of difference,and bled all the rads quite a few times and no air comes out,the towel rail in the bathroom get hot instantly, we have 10 rads in all, I only bought a cheap pump but says it should do the job,any ideas ???

Baxi 80e. Low pressure/pump fault light is on. After reset Boiler does a short run, stops, then fault light comes on and boiler does not fire. Pump feels like it is running. No heating or hot water.

It does seem like you could use a replacement.

I have a Gloworm hideaway boiler (not a combi boiler system) with Grundfos pump. It worked great for 25+years.

The pump finally gave up in March 2017 (defeated by the Beast from the East) and was replaced in by a Grundfos UPS2 15-50/60.

Worked fine until just recently. When the Honeywell control panel turns on the heating the boiler fires up. Upstairs radiators heat up but downstars radiators are not coming on. When the control panel turns the hot water on the water heats up.

The indicator lights on the pump are not coming on.

Do I need a new pump?

If I were to make a guess I would say you don’t need a new pump, considerin upstairs radiators heat up. But I think you should work with an engineer to have your exact case diagnosed.

Hi,

I have a Grundfos Alpha 1 connected to the pipe pumping the water from the fire back boiler to the tank. The pump has seized. I have opened it up but the main turn rotar is stuck in in the back housing and I can’t see behind it. I’m afraid to pull at it to get it out so I can clear any blockage and see if the rotar is turning.

I have tried the screw method to release it before I opened up the housing. It has made no difference. The power to the pump is fine. Is there a way to turn the inside roter part to release it or should I just pull it straight out.

Regards

Unfortunately, we cannot give such advice. Would asking for a professional work make sense? If so, do so here.

I have a very old baxi boiler (about 40 years old) which has been pretty reliable. I tend not to use the timers on the programmer and manually put the water and heat on when required. This evening when putting the system on I noticed that the pump was unusually quiet . It is quite warm and doesn’t seem to be vibrating, yet I still have hot radiators. The only other unusual thing happening is that the water is also heating to quite a high temperature even when the water on switch is off. Would I still have heat in the radiators and water if the pump isn’t working? If not what could be happening and is my boiler safe to use?

If the pump wouldn’t be working you shouldn’t have heat in your radiators. I cannot say for sure what may be causing this. I tend to think the pump is going to fail you soon, but I’m reserved. I think you should call an engineer and have the system checked. See links above in the article for more help in your area.

Hi when I have a bath the central heating heats the water ok but the water pump won’t turn off but when I slightly tap the thermostat on the side of the immersion it goes off can you help me please thanks

We had a new Vaillant boiler fitted when we moved into our house 3 years ago to replace the previous boiler (itself only 12 years old). The pump has always made quite a noise, but it seems to have become much worse over the past couple of months. It makes a rattly, purring sort of noise, which is bad enough during the day but a real problem at night for anyone sleeping in the guest bedroom, adjacent to the garage, where the boiler is located. I complained about the noise to the engineer who installed the boiler when he serviced the boiler last year and the year before, but he said that this was the noise that the pump makes and nothing can be done about it. Is this true?

It may be that the pump is somehow broken, but still works. I reckon having a fully functional pump making that much noise is NOT a good sign. It could break when you expect less.

I have recently had a new boiler and pump installed keeping the original hot water cylinder. I have the hot water timer set for it to come on for an hour every morning but when it comes on, there is a loud band coming from the pump when it starts up, so loud that it can be heard all over the house. Any idea please what is wrong?

Can you confirm the pump is installed horizontally? If the pump is not installed correctly, you will get airlock in a matter of days after bleeding it. Other than that, I’m not sure what to suggest, I’m sorry.

Our heating has been playing up since last winter – COVID really stopped us getting it looked at this year so far. There are numerous “problems” ….

The boiler and pump seem to run OK.

The rads upstairs are generally warm apart from the bathroom which is stone cold.

The hall and guest loo rads are directly below the bathroom – the hall is cold but the loo is hot!

The dining room rad got progressively cooler last time the heating was used and is now just warm at the top.

Pump is quite hot to the touch – hotter than the pipes feeding it

Do I have an air lock somewhere or is the the pump faulty?

Have a Grudfos pump ALPHA2 auto which has worked fine for several years. It always showed 45 in the face

display which various engineers said was ok. The last few weeks this reading has dropped to 40/41 and occasionally 42/43. At the same time two radiators, one upstairs and one downstairs take ages to heat up properly (Hours, not minutes). I had a new Viesmann boiler 1.5 years ago, the system flushed and a magnaclean fitted 4 years ago. The system is checked every year and I have checked that there is no air in the system. What is causing the reduced readings?

Hi, I have a wilo gold rs50 pump with 3 speed settings. The dial for the speed settings seems stuck or really tight and am concerned about forcing it. Is there a correct way of adjusting it or should it turn freely. Thanks

hello there i have installed a baxi combi system boiler .installation is done professionally the only problem is only two radiators are getting less heat.rest of them are red hot.if i am going to put a circulator pump on the flow will that helps as you know system boilers already got a pump inside the boiler,so if i add one more pump where should i put before two port valve of flow or after 2 port valve of flow pipe.kindly give me a suggestion it is highly appreciated and what is the best could you recommend.any step in this regard is highly appreciated.regards kiani

Hi I have the Grundfos UP 15 60. Out of nowhere the heating has stopped working but still get hot water. The pump is really hot to touch and when I unscrew the silver screw the water coming out is hot enough to make a good brew? I’ve tried to turn all the taps off but the water keeps trickling out. Any ideas?

Hello.

Would you able to help.

I have a heating pump replaced yesterday by an engineer in my hiu unit as the old propeller is a bit stiff to rotate.

I now have heating but the problem is the heating pump does not shut off and keep on running constantly. Even when the room thermostat is telling the pump to stop demand for heating as room temp is above comfort setting.

Would you able to help as enginere said they would charge another call out fee to attend the problem.

Kind regards

Hello.

Would you able to help.

I have a heating pump replaced yesterday by an engineer in my hiu unit as the old propeller is a bit stiff to rotate.

I now have heating but the problem is the heating pump does not shut off and keep on running constantly. Even when the room thermostat is telling the pump to stop demand for heating as room temp is above comfort setting.

Would you able to help as enginere said they would charge another call out fee to attend the problem.

Kind regards

My Grundfos circulatory pump is extremely hot to touch. The water and radiators are working fine but there’s a constant humming noise when the heating is on.

Hi I have had a new boiler and a new pump fitted but I am getting a humming noise in the house and tapping sound I have call the company out to sort it they change the pump but still the same

advice on past experience with pumps and systems ,

1.pump to hot to touch . pump has stalled/ jammed causing inner electrical windings in motor to get hot

if left it will eventually burn out , switch off system, and let pump call down, unscrew large screw at top of pump ,water will drip out ,so put something under to catch water, now with a small flat blade screwdriver insert into hole and locate rota end shaft turn in back and forth until it spins freely refit large screw and switch on system you may be in luck if you hear pump running , normal caused by muck in system /

2. old conventional central heating system/ tanks in loft . problem RADS DOWNSTAIRS HOT BUT ONES UPSTAIRS ALL ONLY HALF HOT. problem small header tank in loft that keeps system topped up with water ,the ball valve has seized shut, and slowly the water in the system is evaporating over months some time years and water level in the system is getting lower and lower hence top rads only half hot.

remedy up into loft get hold of ball valve arm move up and down a few times and it should free up and start filling system with water , make sure it shuts of ok .

3. adding bigger rads to system great but can the pump cope with the extra load ? if it can’t your find some rads normally the fer vest away will not get hot , you can try balancing system if that does not work check pump in set on top speed if it is your going to need a stronger/bigger pump good luck bob

Hi during winter my static caravan is winterised but my boiler doesbt get drained as it as anti freeze in . Not been near till today since October because of lockdown. My system was empty no pressure and no electricity pue electric on nothing at the boiler no power had a look found internal pcb board fuse had blown . Replaced pug pressure back up found leaking radiator. Isolated radiator pressure up bleed system water all back on . Put boiler on hot water fired up no problem put heater on can hear gas burner on and heating water but nothing pumping around no noise from pump pump definitely not turning . Do you think it will be pump or pcb board everything hot water wise is perfect .thanks

It could be both, to be honest. An engineer should know how to check…