Power Flushing Costs [And Understanding if You Actually Need One]

The cost of a power flushing service is directly related to how many radiators you have.

The more radiators your central heating system has, the higher the cost. The only difference is the more rads you have, the lower the price per radiator. The question is, do you even need a power flush?

Power Flushing Costs

Number of radiators |

Estimated cost of power flush |

| 6 | £350 |

| 7 | £400 |

| 8 | £440 |

| 9 | £470 |

| 10 | £500 |

| 11 | £525 |

| 12 | £545 |

| 13 | £570 |

| 14 | £595 |

| 15 | £620 |

| 16 | £645 |

The Cost of a Power Flush from British Gas

It’s been mentioned that power flush costs from British Gas will be up to £800. They tend to be around 30-40% more expensive than local engineers.

A Power Flush Might Not Be The Best Route To Take

It’s easy to jump to conclusions. These are the signs most engineers look for when recommending a power flush:

- Radiators don’t heat up evenly (cold at the bottom, and hot at the top).

- The boiler pump is making excessive noise.

- Not all radiators get to full temperature whereas others don’t.

- Water from radiators is murky (usually checked via the bleed valve on the radiator).

- The flow on the boiler is hot, but the return is cold (i.e. hot water is not circulating all the way around the system).

The problem is. This doesn’t necessarily mean that power flushing is necessary, or the best option.

And I’m about to tell you why. First. Let’s quickly explain how a power flush works.

How a Power Flush Service Works

The internals of your central heating system (radiators, pipe-work) will deteriorate over time. And as they do, particles make their way into the water that flows through the boiler.

This can cause not just blockages in the pipe-work and radiators, but also damage parts in the boiler such as the heat exchanger. And that can be costly to fix.

Using a chemical kit and power flush machine, an engineer will force water through the system at a higher flow rate than your boiler usually operates at. Combined with the chemicals they add, this starts to break down these particles, and they’ll be expelled from the system.

But, there is a slight problem

The combined stress of chemicals and extra flow rate can put pressure on soldered joints, and in many cases, can result in leaks.

It’s not always a quick fix, as radiators are sometimes so clogged with sludge they either need a manual flush (so they need to be physically removed), or replaced altogether.

#1 – Check inhibitor levels

Inhibitor is a chemical that is added (and its levels should be checked and maintained) to your heating system. It breaks down particles in the heating system.

A scale reducer (or filter) will catch hard water particles. And a magnetic system filter will then catch magnetic particles.

If inhibitor is not already in the system, dosing the system should be the first point of call.

Sentinel is a leading brand supplying chemicals for boilers. They have an inhibitor test kit here.

#2 – What to do if inhibitor is none existent, or levels are low

Sentinel have a guide that shows you how to top up inhibitor and cleaner in a system. Realistically, you’ll want to speak to a heating engineer, as they’ll have the tools to ensure the right level of chemicals are introduced to the system.

*Quick note: I’ve seen a lot of talk on forums of people topping up their boiler pressure with the external filling loop.

If you do this regularly, you’re going to dilute the chemical content in your system. Losing pressure is not normal. It’s a fault, and needs to be checked out by an engineer.

Once an engineer has dosed the system with inhibitor and/or sludge remover, they’ll usually leave it a week and then drain down the system. This is a simple way to get rid of most of the sludge in a system without putting too much pressure on soldered joints (i.e. a power flush).

#3 – Check pipe-work (micro bore systems)

Sometimes pipework is too small, and not correctly routed.

I had this problem in a maisonette I purchased.

The pipework was 10mm (most systems will use 15mm) and the boiler had been moved from the opposite end of the property into the kitchen. There was also some “questionable” routing of pipework.

All this combined meant even with a manual flush, and a couple of new radiators, there was never a chance the radiators would get to full temperature. The routing of the pipe-work and size of pipes would not make it possible.

It’s worth showing the engineer the pipe-work to check there’s no obvious routing problems. As a power flush can’t fix something that is already broken!

In these cases, re-routing pipework (using 15mm) is going to be the best option. After dosing the system (mentioned above) and draining down, this is likely to solve the problem.

#4 – Replacing radiators is sometimes the cheaper and more energy efficient option

What a lot of engineers don’t suggest is this.

New radiators.

Let’s say a small system has 7 radiators and you’ve been quoted £375. And the price quoted is unlikely to guarantee fixing the problem.

A ball-park for replacements (cost depends on each size of radiator, whether new valves are needed and if there are any pipe-work alterations) is £750.

It’s a lot more expensive, but many manufacturers will claim energy efficiency improvements of 50% compared with radiators manufactured over 15 years ago. This relates to big savings on your energy bill.

If it’s only 1-2 radiators that are causing the problem, replacing those could solve the problem and work out cheaper.

#5 – Check Your Radiators Are Balanced

This might be clutching at straws, but there is a chance when the system was installed, the radiators were not balanced correctly.

This could be the problem if you’ve always had problems with certain radiators getting to full temperature.

It’s also the likely culprit if after draining the system (or seeing water come from the radiator vents), the system appears to be clean.

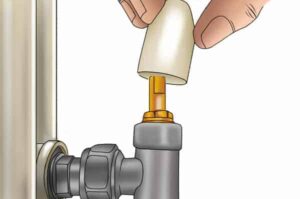

Radiators are balanced using the lock shield radiator valve. It should look like this.

Once you remove the cap, you’ll see something like this.

Ideally, you’ll have an engineer come and balance the radiators correctly.

If you have radiators not getting to temperature, you can open the lock shield valve slightly and see if the temperature increases.

Bear in mind increasing the flow to this radiator, may reduce flow to other radiators in the house. And if the valves are old and rusty, be extremely careful. These things like to leak!

#6 – Check for Low Boiler Pressure, or Pressure Drops

One of the most common problems with boilers is loss of pressure. Without going into huge detail here, this can be due to:

- Leaks in the system or on valves (do some visible checks underneath the boiler, radiators and radiator valves)

- A build-up of air in the system (which can be removed by bleeding the radiators and towel rails).

- Leaks coming from the auto air vent on the boiler, or expansion vessel.

Get a breakdown engineer to try and fix this issue first. As the problems your experiencing might be linked to the boiler and not a build-up of sludge in the system.

If the boiler is on it’s last legs, it might be worth considering a boiler replacement.

Conclusion

If you’re set on a power flushing service and understand the costs, a local engineer is going to be a lot cheaper than a national company.

However, before you agree a deal, make sure the engineer has done the necessary checks to ensure it is a power flush that is needed, and it’s not a problem with roots elsewhere (such as the boiler).

Any questions? Leave a comment below and we’ll do our best to help you out.

I got a new boiler fitted four years ago we have 8m pipe work and 15/20 year old radiators keep getting F9 fault (low pressure) had boiler fully checked with some new parts pump/vessel replaced now change now being advised to get power flush what do you think

It should help considering your radiators are that old.

Sometimes the rads get warm all over and other times they stay very cool they never get so hot you can’t touch them. The system was drained down 2 yrs ago. The pump was replaced 2 yrs ago. The return pipe to the boiler is cool. We have always had fermox in the system. The. Boiler is serviced every year. British Gas eng came out and said power flush required. Worried about power flush it case it causes leaks. We have 10 rads. Tank in loft.

If done correctly a power flush shouldn’t break any of your radiators.

Can you please message me a quote 4 chemical flush there r 4 radiators on the central heating system

Please see links above, in the articel.

Radiators coming on with hot water even though central heating turned off! Plumber says we need a power flush. Is he correct?

I doubt you get hot radiators and the central heating is off. Where is the hot water coming from??

Hi thankyou for all your info regarding power flush, I would appreciate your thoughts on my situation. 4 bed detached house built 4 years ago, only 1 radiator out of 12 that is causing a problem.

Practically cold all over with the exception of a small amount of heat at the top rim about 3 inches.

Tried bleeding all radiators and water is a dirty brown colour. (For this reason we thought we may need a power flush)

British gas engineer thought a pipe in wall may be kinked and suggested we get that burst open to check and straighten to solve the problem, but after reading info on internet maybe we do need the power flush which is quite expensive, unsure what to do as house only 4 years old, would appreciate your independent advice

Hi Cliff, it could be both, I reckon. There’s no harm in having a power flush, except to your wallet. I don’t think you’ll be having problems this year, so I guess it depends where that faulty radiator is. If you need it at full power, then yes, power flush. I’m not sure what to tell you about kinked pipes without actually seeing. See our links above for very knowledgeable engineers. They should know exactly what is going on.

I had a yearly service on the boiler. The engineer showed me a glass cylinder filled with brown water and suggested I got a power flush done. The system doesn’t have any problems and all radiators work fine.

Would you leave thing alone for now or go for the recommended flush?

Thank you

I guess it depends. Would you change your brakes if they are close to the mark, but they haven’t reached the mark? The only problem with boilers is you don’t have a mark. When you reach the “mark” it’s game over for heating and hot water. Personal opinion: I would do a power flush, yes.

We are possibly having a new Vaillant boiler fitted shortly, nothing done to the system since 1999 where we updated from microbore system and a Worcester boiler. If we have British Gas we are told have the system flushed to prevent muck/dirt damaging the new boiler.

Would you agree a flush should be undertaken.

Regards

Peter

A flush is something you should do if you install a new boiler and nothing has been done to the pipes/radiators for the last 20 years. We highly agree, yes.

Good evening and thank you for that informative post. I am considering a flush but now maybe I dont need one. I am thinking of using sentinel x100 in the first instance. Can I add this directly to a F+E tank in my loft? Thank you.

I think so, but you may want to check with an engineer, too.

Hi I have 5 radiators in my house but 2 only heat up at the top. I’ve had them bled but it didn’t really help. I have my boiler serviced regularly. So if you could give me any advice on if I should have the system flushed or just replace the 2 radiators that are troublesome. I would really appreciate it. Thank you

Joan.

Hey Joan, usually when radiators are cold at the top it’s a bleeding problem. If they are cold at the bottom it can be a sludge/build-up problem and a power flush may be needed.

I’m not sure what could be the problem with yours, but things I would check include your pump, too. Maybe it’s not working properly? Not pushing water well enough? Please see our links above for engineers in your area.

Hi. My oil boiler keeps locking out, it’s been fitted with a new pump and new motor but still locks out. Two of my radiators are cold at the bottom. Do you think sludge is the problem.

If you’re certain it’s not the pump, then yes, it COULD be sludge. An engineer should take a look though.

My radiators get hot no problem but I can’t get hot water at all from the system valiant boiler is just4 years old , so have to keep using my hot water tank in my airing cupboard what can I do it’s getting very expensive