Vaillant Boilers’ Problems: How to Fix the Most Common Vaillant Faults

Vaillant make some of the highest-quality boilers out there, and yet, from time to time, even these appliances malfunction. And, as is the case with all boilers, common Vaillant boiler problems need to be diagnosed via troubleshooting.

In this guide, we will explain why Vaillant boilers get problems and talk about ways to fix them.

It’s important to understand that all work should be completed by a Gas Safe boiler engineer.

Consider getting an expert to quote the repair cost.

Vaillant Boiler No Hot Water, or Other Problems?

First things first, let’s go over the top 10 Vaillant boiler problems; we’ve listed the corresponding fault codes for some of these.

#1. Boiler Leaks

Possible fault codes: F22

Boiler leaks can happen for various reasons, such as corroded or faulty components, broken seals, or excessive pressure.

Unfortunately, boiler leaks have the potential to cause major damage to both your boiler’s electrical components and your property.

If you think that your boiler (or any other part of your central heating system, for that matter) is leaking, consult with a Gas Safe registered engineer without delay.

#2. Hot Water, But No Heat

If your Vaillant boiler gives hot water but no heating, you may have several issues on your hands:

- Air trapped in the radiators

- Combi boiler that’s set to produce hot water but no heat

- Malfunctioning diverter valve

- Other faults with the boiler or heating system

The first 2 causes are relatively inexpensive to fix. You can get trapped air out by bleeding your radiators, and it won’t take you long to find if your combi isn’t set to produce heat.

The last 2, on the other hand, will require a Gas Safe engineer’s involvement.

#3. Boiler Pressure Is Low

Possible fault codes: Vaillant F22

Like all boilers out there, Vaillant’s boilers get problems with low pressure because of leaks. If that’s what’s causing the low pressure, then the boiler leak is your true culprit.

However, your boiler pressure could also seem low because of a faulty pressure sensor.

#4. No Heat, No Hot Water

Possible fault code: F20-F25, others

If your Vaillant boiler doesn’t produce hot water or heat, it could be because:

- The boiler has locked out for a safety reason

- There’s no power or gas supply to your boiler

- There’s some other problem affecting your entire system

If you’ve eliminated the obvious, like a lack of electricity or gas to your property, or a tripped circuit, it’s time to call a Gas Safe registered engineer to investigate the problem.

#5. Boiler Not Responding to Thermostat

When the room temperature is below the thermostat setting and your boiler is not heating the radiators, chances are that there’s an issue with a thermostat. Try replacing the thermostat’s batteries (if it’s got them), or moving it closer to the receiver. Otherwise, get in touch with the thermostat manufacturer and attempt to troubleshoot the problem with their representative.

#6. Frozen Condensate Pipe

Possible fault code: F28, F29

If your Vaillant boiler is not turning on during a chilly winter day, there’s a chance that it locked out because the condensate pipe froze over. This is a safety measure that will cause the boiler to lock out unless the pipe is unblocked. In most cases, condensate pipes are simple enough to thaw out with warm water.

#7. Boiler Kettling Noise

Possible fault code: F20

Is your boiler making a kettling noise? Vaillant’s boilers have this problem when their internal components, including the heat exchanger, get clogged with limescale. When this happens, the boiler heats up the water too quickly, and the resulting steam produces the sound known as “kettling”.

Your Gas Safe heating engineer will determine whether the limescale build-up can be removed, or if you have to replace the clogged component altogether. If this issue affects your heat exchanger, it usually makes more financial sense to replace your boiler altogether.

#8. Vaillant Boiler Keeps Locking Out

In the event that your Vaillant boiler is not turning on after abruptly shutting off, it’s likely locked out as a safety precaution. Boiler lockouts can happen for a wide range of reasons, but most are rooted in safety. Here are some underlying causes of a boiler lockout:

- Fan faults

- Pressure too high

- Repeated ignition failure

- PCB faults

- Gas valve malfunction

- System blockage

Only a Gas Safe engineer can safely diagnose the problem and recommend a solution.

#9. Pilot Light Not Coming On

A pilot light that’s not staying on, or won’t ignite, is usually the consequence of debris blocking the pilot light jet. Alternatively, the problem can point to a problem with the gas supply. In either scenario, the investigation entails taking the boiler apart — something you should always leave for a Gas Safe engineer.

#10. Vaillant Boiler Making Noises

Boilers, including those made by Vaillant can produce a variety of noises. Here’s a brief summary of what they typically mean:

- Banging, gurgling — air trapped in the system

- Tapping, clicking — ignition faults

- Humming, vibrating — seized pump rotor

- Whistling, kettling — limescale build-up in the boiler’s components

You can read our full guide to boiler noises here; alternatively, consult with a Gas Safe engineer.

Common Vaillant Boiler Fault Codes

Now, let’s continue with our Vaillant boiler troubleshooting guide and dive deeper into what some of the common error codes mean, and how to resolve them.

Vaillant F22 Boiler Fault

One of the most common Vaillant boiler problems is the F22 fault code. This problem is common on the Ecotec Plus and Ecotec Pro models, in particular the Vaillant Ecotec Pro 28.

This code is connected to a lack of pressure or water.

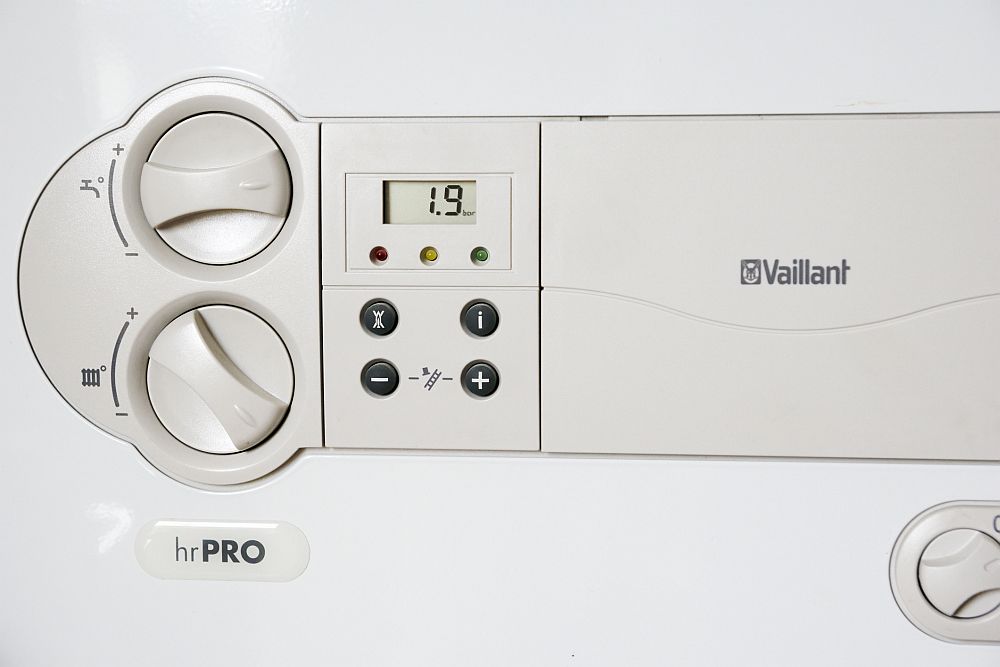

Most newer boilers have sensors that will constantly measure the pressure of the water in the system. If there is a pressure drop, the sensors kick in and display an error code.

You may find that there is a red light on the display board. This is simply a clarification that the boiler is not firing correctly.

The F22 fault will automatically put the boiler into a limp mode, much like a car would if the ECU detects a problem. If it continues firing without enough water, it could damage expensive parts within the boiler.

-

How to Fix the Vaillant F22 Boiler Fault

Many websites suggest that a simple fix is using the filling loop to top up the pressure on your Vaillant boiler.

Whilst this in theory is correct, it doesn’t fix the problem. A boiler doesn’t just lose pressure for no reason, so the fault needs to be fixed.

Boilers tend to sit at 1.5 bar of pressure. If it has dropped below this, topping up via the filling loop is only likely to cause further damage.

Your system should be dosed with inhibitor, and by topping up the boiler’s pressure using the filling loop, you are diluting the chemicals that are protecting the system.

A Gas Engineer will need to troubleshoot the boiler to determine whether the F22 fault is related to:

- Lack of pressure

- Lack of water

- Both of the above

Leaks are one of the most common reasons a boiler loses pressure (and water). They can come from radiators, towel rails, radiator valves, pipe work, air vents or even expansion vessels.

Another common cause is a build-up of air in radiators.

However, a faulty pump could also be the culprit. A lot of older boilers from Vaillant used Wilo pumps. They are prone to faults and over time they seize or start to leak. This would be the cause of low pressure and lack of water.

Vaillant F27 Boiler Fault

The next common Vaillant boiler fault we come across is the F27 fault. This error means that the boiler’s sensor has noticed that the flame is not correct.

This could be for one of several reasons:

- The PCB is not working correctly, and the flame is working fine.

- The gas valve is not working correctly, and therefore, the boiler is not getting the correct amount of gas to produce the correct flame.

- The flame sensor is detective and needs replacing.

In some cases, the boiler doesn’t fire at all. In this instance, a likely cause is ignition leads.

-

How to Fix the F27 Vaillant Boiler Fault

This is certainly not one of the easy Vaillant boiler problems to troubleshoot.

A Gas Engineer will need to come and inspect the boiler and its internal components to diagnose the problem.

Where the fault relates to anything but the PCB, usually replacing the parts is the most economical option (assuming the rest of the boiler looks like it is in good condition).

Like many boiler problems, if it relates to the PCB, it’s usually much more economical to fit a new boiler.

The cost of a PCB and labour for installation can be as much as £500. For an old boiler that is not likely to last more than a few years, replacing the PCB is certainly not the best option. And you can get prices for a new boiler within 90 seconds, using Heatable’s handy quote form.

Vaillant F29 and Vaillant F28 Boiler Faults

The Vaillant F28 boiler fault code is not as common as the F22 or F27. And the Vaillant F29 code will be displayed after similar symptoms are shown to the F28 fault code.

This fault code will usually be displayed after you experience a boiler lockout, and you have no supply of heating or hot water.

It relates to one thing; lack or no supply of gas.

-

How to Fix the Vaillant F29/F28 Errors

Being a gas related fault, you shouldn’t try to attempt to fix this problem yourself. Always call a Gas Engineer.

From a fault troubleshooting point of view, you can try one thing.

If you have any other gas appliances (such as a hob), check that they work.

It’s an unlikely scenario, but it could be a problem with the gas supply (meter has run out, supplier has cut off the gas or repairs to gas main in your road).

If this is not the issue, a Gas Engineer will be able to start their troubleshooting process by analysing:

- Gas valve operation and adjustment settings

- Condition of the ignition leads

- Condition and operation of the ignition unit

- Check the air inlet duct

What kind of fuel does your boiler use?

Fixed price online with next day installation

Vaillant F61 Boiler Fault

Similar to the F28 and the F29, the F61 Vaillant fault code means there’s no gas supply. Why? Because there’s a problem specifically with the gas valve, which may be seized or stuck.

The culprit to showing the F61 error code is your printed circuit board (PCB) which monitors all sorts of sensors to determine whether your boiler is functioning correctly. If your PCB senses issues with the gas valve, the supply will be cut off and a Gas engineer will need to pay you a visit in order to have this fixed.

Please note, only a Gas Safe boiler engineer will be able to assess the damage and carry out the repair because they are the only ones qualified to work on gas appliances

Vaillant F75 Boiler Fault

Out of all the Vaillant boiler faults we come across, the F75 fault code is the most common. We see it particularly often on the Eco Tec Plus range and the Eco Tec Pro 28.

The Vaillant service manual will list the following error in relation to the F75 fault code.

“Water pressure sensor and/or pump defective, air in heating installation, too low pressure in boiler; connect external expansion vessel to return.”

So what you have here is three possible fault scenarios:

- The boiler’s central heating pump

- The boiler’s pressure sensor

- Both above are faulty

-

How to Fix the F75 Vaillant Boiler Fault

If It’s the Pump

I’ll say right now, the most typical cause of the F75 fault is the pump. And there is a good reason for that.

Most newer Vaillant boilers use top quality Grundfos pumps. However, this has not always been the case.

Older Vaillant boilers used Wilo pumps, which are known for being extremely unreliable. In fact, they were the most likely to break in these older boilers.

You can do a quick manual check of the pump on your Vaillant boiler by starting up the heating, or running the hot water.

After the boiler fires up, you’ll hear a gentle humming noise. So, everything being well, this should be the noise of the pump circulating the water through your pipework and radiators.

If there is no sound after starting up the boiler, there’s a good chance that the pump is the cause.

Older Wilo pumps ended up getting seized bearings (especially after a long period of non-use) and a replacement is the best option.

If you need to replace the pump, most gas engineers will charge you around £300, with installation.

If It’s the Pressure Sensor

The other scenario is that it’s the pressure sensor causing the F75 boiler fault.

Like the Wilo pumps, the older Vaillant pressure sensors were not particularly durable. In fact, they were revised 3 times over a short period.

Heating systems have a lot of debris build up (carbon and sludge) over time. This can block the pressure sensor and cause it to be defective.

A Gas Engineer will be able to diagnose the boiler fault and take the appropriate action.

For the pressure sensor, the cost will be just under £250.

Vaillant Boiler Still Not Working?

Need help from qualified boiler engineers? > Click Here <.

If your old Vaillant breaks often and repairs are proving to be a temporary fix, it may be time to consider a replacement — especially if your boiler is out of warranty and you don’t have a boiler cover plan.

A good place to start looking is Heatable. The online boiler installation company have a nationwide network of installers and offer some of the most competitive boiler installation prices on the market. You can get your own fixed-price boiler quote by filling in Heatable’s anonymous questionnaire.

What’s Next?

If your Vaillant boiler fault not listed, or there’s any other question you’d like to ask, please leave a comment below and we’ll get back to you as soon as possible.